| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : AVIC-Flight

Model Number : Standard Size

Certification : ISO9001:2015,ROHS

Place of Origin : China

MOQ : 100pcs

Price : Negotiate

Payment Terms : T/T, L/C

Supply Ability : 50000pcs/day

Delivery Time : 15 days

Packaging Details : 1000pcs/bag

Application : Industry,Sheet Metal

Packing : 1000 Pcs

Length : 1-3D,custom

Item name : Wire Thread Insert for Thread Repair

Type : DIN8140

Certificate : ISO SGS ROHS

Applicable scope : Various materials

Payment method : L/C D/A D/P T/T

SUS 304 Ordinary Steel Wire Threaded Insert M5 Metal Spiral Spring Threaded Insert

Information

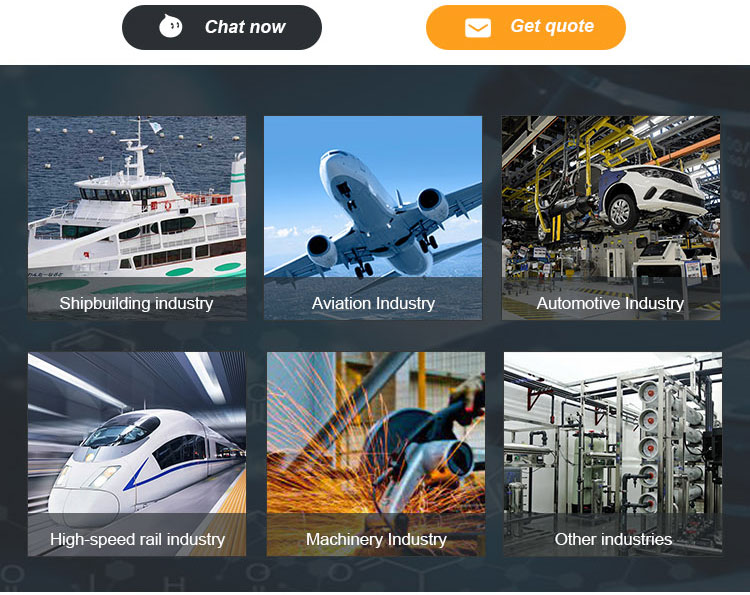

The thread insert portfolio of wire threaded inserts includes offerings of a variety of configurations whether it be plating, material, locking, or non-locking variants that make it fully adaptable and configurable for industries spanning automotive, industrial, aerospace, and defense. There is a strong industry trend toward the lightweighting of materials, yet achieving structural integrity of bolted or fastened joints. thread insert by nature of its design is an ideal solution to be incorporated as part of these assemblies.

Use

1. Enhancing the connection strength and improving the connection conditions. Low-strength materials such as aluminum and magnesium are selected for the wire thread insert, which can avoid slippage and wrong teeth, and obtain excellent connection performance.

2. Wear resistance. Used in frequently disassembled parts, it can greatly improve the service life of the thread.

3. Increase the bearing surface. It is used in places where strong connection force is required and the diameter of the screw hole cannot be increased.

4. Anti-loosening. It is especially used in occasions where products such as spacecraft require a high insurance factor.

5. Easy to maintain. Install the damaged screw hole into the wire screw sleeve, and continue to use it after repairing to avoid the possibility of damage to the workpiece.

| Product Name | Stainless Steel SS04 Thread Insert |

| Material | Stainless steel |

| Color | natural color |

| Standard | DIN,ASME,ASNI,ISO |

| Used | Building Industry Machinery |

| Lead time | 7-15days |

| DIMENSION OF DIN8140 WIRE THREAD INSERTS | ||||||||||

| D | P | L1 | d1 | D | P | L1 | d1 | |||

| min | max | min | max | |||||||

| M2 | 0.4 | 1d | 2.6 | 2.8 | M8 | 1.25 | 2d | 9.85 | 10.1 | |

| 1.5d | 2.5d | |||||||||

| 2d | M10 | 1.5 | 1d | 12.1 | 12.5 | |||||

| 2.5d | 1.5d | |||||||||

| M2.5 | 0.45 | 1d | 3.3 | 3.5 | 2d | |||||

| 1.5d | 2.5d | |||||||||

| 2d | M12 | 1.75 | 1d | 14.4 | 14.8 | |||||

| 2.5d | 1.5d | |||||||||

| M3 | 0.5 | 1d | 3.8 | 4 | 2d | |||||

| 1.5d | 2.5d | |||||||||

| 2d | M16 | 2 | 1d | 19 | 19.4 | |||||

| 2.5d | 1.5d | |||||||||

| M4 | 0.7 | 1d | 5.15 | 5.35 | 2d | |||||

| 1.5d | 2.5d | |||||||||

| 2d | M20 | 2.5 | 1d | 23.7 | 24.2 | |||||

| 2.5d | 1.5d | |||||||||

| M5 | 0.8 | 1d | 6.35 | 6.6 | 2d | |||||

| 1.5d | M24 | 3 | 1d | 28.6 | 29.1 | |||||

| 2d | 1.5d | |||||||||

| 2.5d | 2d | |||||||||

| M6 | 1 | 1d | 7.6 | 7.85 | M30 | 3.5 | 1d | 35.2 | 35.7 | |

| 1.5d | 1.5d | |||||||||

| 2d | 2d | |||||||||

| 2.5d | M36 | 4 | 1d | 42.1 | 42.6 | |||||

| M8 | 1.25 | 1d | 9.85 | 10.1 | 1.5d | |||||

| 1.5d | 2d | |||||||||

Install

Special tools for wire thread inserts are required to install wire thread inserts, which mainly include special taps for wire thread inserts, wire thread insert installation wrenches, punches, unscrews, and bottom hole plug gauges for the internal thread of steel thread inserts. The taps are used for processing. The installation threaded bottom hole of the wire thread insert, the installation wrench is used for the installation of the wire thread insert, the punch is used for the punching of the mounting shaft, the unloader is used for the disassembly of the threaded sleeve, and the bottom hole plug gauge is used for the inspection of the bottom hole of the installation.

|

|

SUS 304 Ordinary Steel Wire Threaded Insert M5 Metal Spiral Spring Images |